Imagine a world where you could own a home without breaking the bank—a place where the dream of a cozy, affordable house isn’t just a distant fantasy but a reality built in under a week. For many Americans, the soaring median home price of over $422,000 feels like a punch to the gut, and with mortgage rates still stinging, that dream seems further away than ever. Yet, in a small Colorado town, a company is churning out homes like they’re assembling Lego sets, promising to reshape the housing landscape. Could this be the key to reviving the American Dream of home ownership?

The Promise of Modular Homes

The housing market is a mess—let’s not sugarcoat it. A nationwide shortage of nearly four million homes, sky-high prices, and a construction process that feels stuck in the Stone Age have left countless families priced out. But modular homebuilders are stepping up, offering a glimmer of hope with homes that are faster, cheaper, and just as sturdy as traditional builds. These aren’t your grandma’s mobile homes; they’re sleek, modern, and built to last, all while slashing costs and construction time.

What Makes Modular Homes Different?

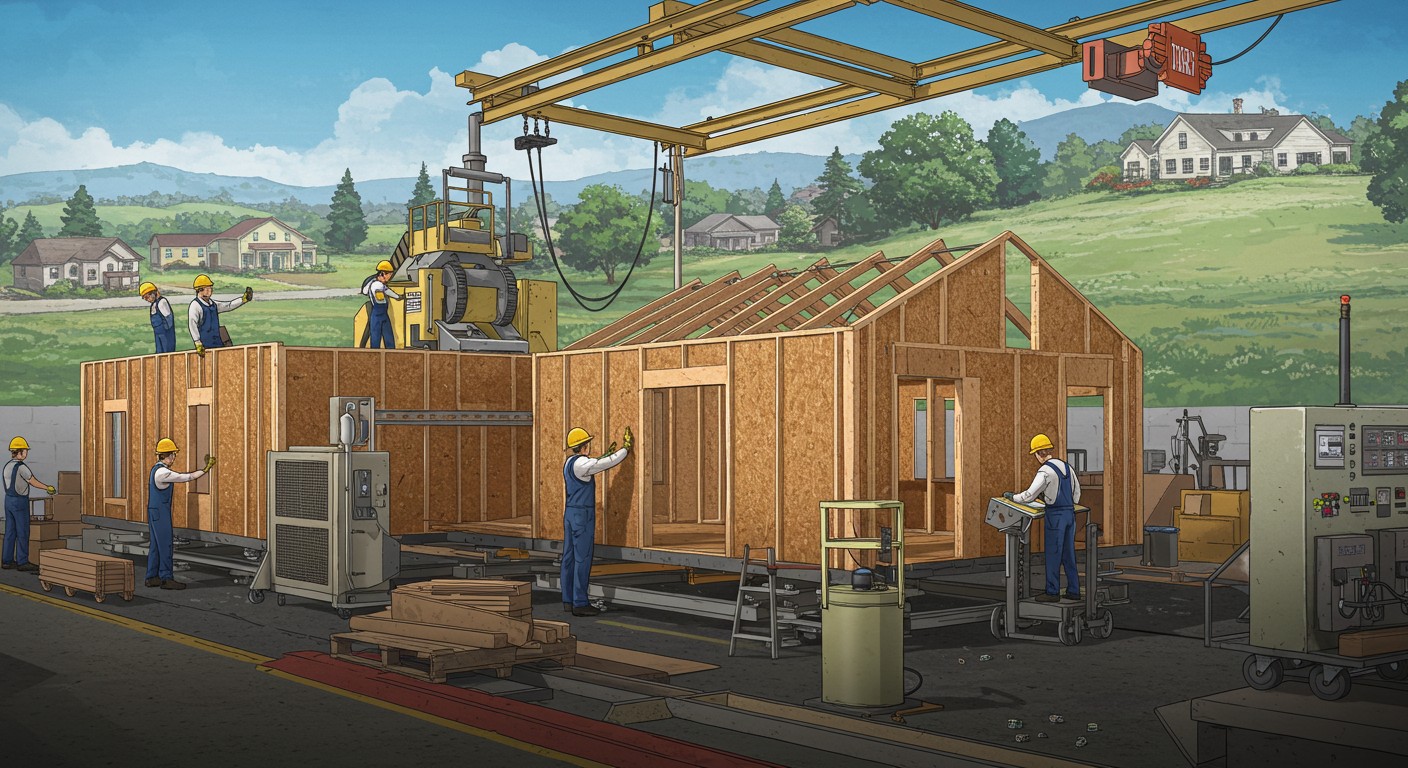

Unlike traditional stick-built homes, where every nail and board is hammered on-site, modular homes are constructed in a factory. Think of it like a high-tech assembly line, where each piece of the house—floors, walls, even the plumbing—comes together under one roof. This controlled environment cuts down on weather delays, reduces waste, and keeps costs in check. I’ve always found it fascinating how something as complex as a home can be pieced together like a puzzle, ready to be shipped and set up in days.

- Faster construction: Homes are completed in as little as seven days.

- Cost savings: Up to 20% cheaper than traditional builds.

- Quality control: Factory settings ensure precision and consistency.

The result? A house that’s not only affordable but also built to the same codes as any other home, blending style with practicality. It’s no wonder companies like these are catching attention nationwide.

A Case Study in Crisis Response

Picture this: a town ravaged by wildfires, families left homeless, and the government scrambling for solutions. In 2023, a devastating fire tore through a historic Hawaiian city, destroying nearly 2,000 homes. Enter modular homebuilders, who didn’t just provide temporary fixes but delivered 82 vibrant, modern homes in just months. These weren’t flimsy trailers but one-, two-, and three-bedroom houses, costing between $165,000 and $227,000 each, funded by federal aid.

“This was the first time we offered modular homes instead of trailers for disaster relief. It’s a game-changer.”

– Federal agency spokesperson

These homes were designed with care, blending functionality with aesthetic appeal, proving that modular construction can step up in a crisis. The speed—two months from factory to move-in—showcases what’s possible when innovation meets urgency.

Tackling the Affordability Crisis

The numbers don’t lie: with a median home price of $422,000 and a housing shortage that’s left millions in the lurch, affordability is a national crisis. Modular homes could be the answer, offering a lifeline to teachers, firefighters, and young families who’ve been priced out of the market. By building in a factory, companies can cut costs without cutting corners, delivering homes that fit a range of budgets.

Take a small Colorado company as an example. Starting with a mission to house local workers in pricey ski towns, they’ve expanded their vision to address the broader housing crisis. Their factory, the size of two football fields, hums with activity as workers move homes from station to station, finishing each in about a week. It’s like watching a choreographed dance—efficient, precise, and a little mesmerizing.

| Home Type | Construction Time | Cost Range |

| Modular Home | 7 Days | $165,000–$227,000 |

| Traditional Home | 6–12 Months | $300,000+ |

This efficiency doesn’t just save time; it saves money, making home ownership possible for those who thought it was out of reach. But can it scale to meet national demand?

Challenges and Opportunities

Modular construction isn’t perfect. For one, it’s still a small player in the housing game, making up just 1–3% of new single-family homes annually. The industry took a hit after the 2008 housing crash, with fewer factories left to meet demand. Plus, there’s a stigma—some folks still think modular homes are just glorified trailers. But that’s changing as designs get sleeker and more customizable.

“Modular homes are built to the same codes as traditional homes, but they’re faster, greener, and often more affordable.”

– Housing industry expert

Another hurdle? Scaling up. While modular homes work wonders in small towns or disaster zones, meeting the needs of urban areas with massive housing shortages is a taller order. Yet, the potential is huge. States like New York are starting to embrace modular construction as a key to boosting affordable housing supply, and that’s just the beginning.

Why Modular Homes Matter

Let’s get real: owning a home isn’t just about having a roof over your head. It’s about stability, pride, and building wealth for the future. Modular homes offer a path to that dream for people who’ve been priced out of the market. They’re not just affordable; they’re sustainable, cutting waste by nearly 25% compared to traditional builds. Plus, they’re built by skilled workers in safe, indoor environments, which means fewer delays and better quality.

- Speed: Homes built in days, not months.

- Affordability: Lower costs open doors for more buyers.

- Sustainability: Less waste, greener building process.

I can’t help but think this could be a turning point. Maybe modular homes are the shake-up the housing industry needs to make the American Dream attainable again.

Looking Ahead: A New Era for Housing?

The future of modular homes is bright, but it’s not without its growing pains. As more states and cities recognize their potential, we could see a shift in how homes are built nationwide. From disaster relief to urban housing projects, modular construction is proving it’s more than a niche—it’s a solution. Companies are already expanding into new markets, from rural towns to affluent suburbs, offering everything from cozy starter homes to multi-million-dollar designs.

What excites me most is the ripple effect. Affordable homes mean stronger communities, less financial stress, and a chance for more people to plant roots. It’s not just about building houses; it’s about building hope. Could this be the moment we finally tackle the housing crisis head-on? Only time will tell, but I’m betting on modular homes to lead the charge.

The housing crisis might feel like an unbeatable giant, but modular homes are slinging stones at it with precision. By combining speed, affordability, and quality, they’re rewriting the rules of homebuilding. Perhaps the most exciting part is how they’re bringing the American Dream back into reach—one factory-built home at a time.