Have you ever stood in a packed lunch line, watching the staff hustle to scoop rice, grill chicken, and layer toppings, all while trying to keep smiles on their faces? It’s chaotic, right? But what if much of that frenzy happened out of sight, handled by precise machines that never tire or spill a grain? That’s the reality creeping into some of our favorite fast-casual spots, and it’s turning heads in the investment world.

The Rise of Automation in Fast-Casual Dining

In a year that’s been tough on the restaurant industry – with stocks tumbling and customers tightening belts – something interesting is happening behind the scenes. Big players are betting big on technology to solve age-old problems like speed, consistency, and labor shortages. One startup out of California is catching serious attention for its clever approach to automating the heart of the operation: the makeline.

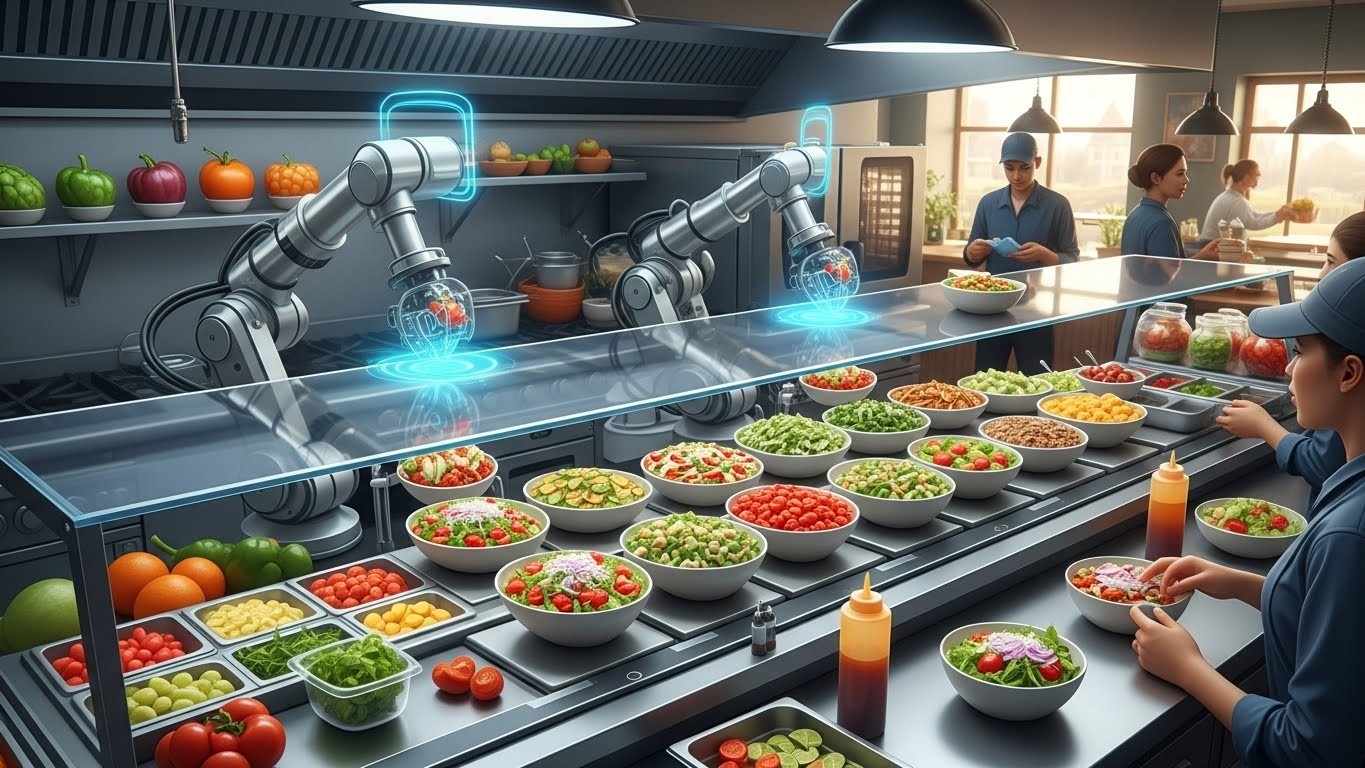

These aren’t clunky robots flipping burgers in view of everyone. Instead, think of elegant systems tucked away, assembling bowls and salads with remarkable precision. It’s the kind of innovation that makes you wonder why it took so long, especially when lines snake out the door during peak hours.

Why Major Chains Are Investing Heavily

Competition in the fast-casual space is fierce. Places known for fresh, customizable meals face constant pressure to serve food quickly without sacrificing quality. Labor issues don’t help – finding reliable staff for repetitive tasks has been a headache for years. Enter automated solutions that promise to smooth out those pain points.

One company has secured substantial backing from two leaders in the Mediterranean and Mexican grill segments. Through venture funds and direct commitments, they’ve poured in tens of millions combined. This isn’t just pocket change; it’s a clear signal that these chains see real value in scaling the technology across their locations.

Perhaps the most intriguing part is that these investors are essentially competitors. Yet they’re aligning on this tech because the benefits outweigh any rivalry. In my view, that’s a strong endorsement – when direct rivals back the same solution, you know it’s addressing core industry challenges.

We’re probably making a bowl every 10 to 15 seconds. At peak throughput, we have more capacity usually than they do demand, especially for lunch and dinner rushes.

– Hyphen co-founder and CEO

That kind of speed is game-changing. It means shorter waits, happier customers, and staff freed up to handle greetings, custom requests, or even upselling. No more frantic scrambling when a big order comes in.

How the Technology Actually Works

Picture a long table-like setup where orders flow in digitally. Below the surface, a series of coordinated robotic components dispense ingredients with exact portions. Everything moves along a conveyor, emerging perfectly assembled at the end for final touches or handover.

The beauty is in the subtlety. Customers don’t see whirring arms or beeping machines. It feels seamless, almost magical. Staff can still add personal flair on top while the heavy lifting happens underneath. It’s designed for high-customization menus – exactly what fast-casual thrives on.

- Precise portion control down to the gram

- Consistent assembly every single time

- Handles peak rushes without breaking a sweat

- Allows human workers to focus on service and interaction

- Minimal downtime with manual override options

Reliability stands out too. These systems reportedly operate smoothly most of the time, and when maintenance is needed, employees can step in just like turning an escalator into stairs. Practical engineering at its best.

The Financial Side: Costs and Returns

Upfront, these makelines represent a significant investment – ranging from fifty to a hundred thousand dollars per unit. That’s not trivial for any operator. But the payback period is surprisingly quick, often under twelve months according to early adopters.

How? Through labor efficiencies, reduced waste, and higher throughput. When you portion everything perfectly, food costs drop noticeably. Less over-scooping means ingredients stretch further. Add in the ability to handle more orders per hour, and the numbers start making sense.

Recent funding rounds are fueling expansion. Partnerships with manufacturing firms will ramp up production, making units more readily available. Pilot programs are already underway, with one chain testing modifications after initial restaurant trials, and another planning dedicated lines for online orders.

Tackling Food Waste in an Industry Hot Seat

Restaurants have long struggled with waste. Over-portioning, spoilage, prep errors – it all adds up. Sustainability pressure from customers and regulators only heightens the issue. Automated systems offer a direct counterpunch.

By tracking and dispensing exact amounts, these machines minimize excess. Data collected can inform better forecasting and inventory management. It’s not just about saving money; it’s increasingly about responsibility. Consumers notice when brands take tangible steps toward efficiency.

In my experience following food tech trends, waste reduction often becomes the sleeper benefit that keeps operators hooked long-term. The immediate speed gains grab headlines, but the ongoing cost savings build loyalty.

From Food Truck Dreams to Industry Solution

The origin story adds a human touch. Founders initially built a fully robotic food truck – ambitious and ahead of its time. Launching just before global disruptions forced a pivot. Suddenly, licensing technology to existing restaurants made far more sense than operating solo.

That adaptability speaks volumes. Many startups cling to original visions and falter. Here, founders listened to partners and redirected efforts toward broader impact. The result? A focused product solving real problems for established chains.

We decided it just made a lot more sense to help restaurants that are already around today.

– Company co-founder reflecting on the pivot

Where This Tech Fits Best

Not every segment is ripe for this approach. Quick-service burger joints with simpler menus might not see the same returns. The sweet spot lies in high-volume, high-customization concepts – think build-your-own bowls, salads, or wraps.

Digital orders represent another prime opportunity. A dedicated back-of-house line handling app and delivery requests could transform operations. No more clogging the front line with takeaway tickets during rushes.

- High customization menus benefit most from precision

- Peak-hour volume demands reliable throughput

- Online order growth needs separate handling

- Campus and corporate dining offer expansion potential

Conversations are apparently happening with major brands and foodservice providers for non-traditional locations. The vision extends beyond standalone restaurants.

Broader Industry Context in a Challenging Year

Let’s zoom out. Many fast-casual stocks have taken serious hits recently. Younger demographics pulling back spending, rising costs, saturation – pick your pressure point. Innovation feels like the logical response.

Other players have made moves too. Some sold off robotics divisions, while others double down on proprietary tech. The landscape is shifting rapidly. Automation isn’t new, but targeted applications like these makelines seem particularly well-timed.

Will every chain adopt similar systems? Probably not overnight. But the investment votes from industry leaders suggest a meaningful trend. Efficiency gains could help margins in ways traditional methods can’t match anymore.

Looking Ahead: Software and Data Layers

Hardware impresses, but the future likely lies in software. Collected data on ingredient usage, order patterns, and prep times opens doors to smarter operations. Scheduling tools, predictive inventory, dynamic pricing – possibilities abound.

Founders hint at evolving beyond pure assembly into back-of-house intelligence. That holistic approach could create stickiness, turning one-time hardware sales into ongoing partnerships.

Frankly, that’s where things get really exciting. Physical automation solves today’s headaches; data-driven insights could prevent tomorrow’s. The combination might prove transformative.

Final Thoughts on Restaurant Evolution

Walking into a restaurant ten years from now might feel subtly different. Lines moving faster, orders more consistent, staff seemingly less stressed. Some of that magic will come from clever engineering hidden from view.

Investments flowing into targeted automation reflect confidence in that future. When established operators open their wallets – especially competitors collaborating indirectly – it’s worth paying attention.

The restaurant business has always adapted to survive. From drive-thrus to apps to delivery integrations, change is constant. This wave feels particularly promising because it enhances rather than replaces the human elements we love: fresh ingredients, customization, and friendly service.

Next time you’re grabbing a quick bowl for lunch, take a moment to appreciate the orchestration – visible and invisible – making it possible. The industry is evolving, one precisely portioned scoop at a time.

(Word count: approximately 3250)