Have you ever wondered how your favorite gadgets, clothes, or even snacks end up in your hands at such affordable prices? The answer lies in a game-changing process that’s been shaping industries for over a century: mass production. It’s the backbone of modern manufacturing, churning out identical products at lightning speed. But while it’s made life more convenient, it’s not without its quirks. Let’s dive into what makes mass production tick, its upsides, its challenges, and how it’s evolved to keep up with today’s demands.

What Makes Mass Production So Powerful?

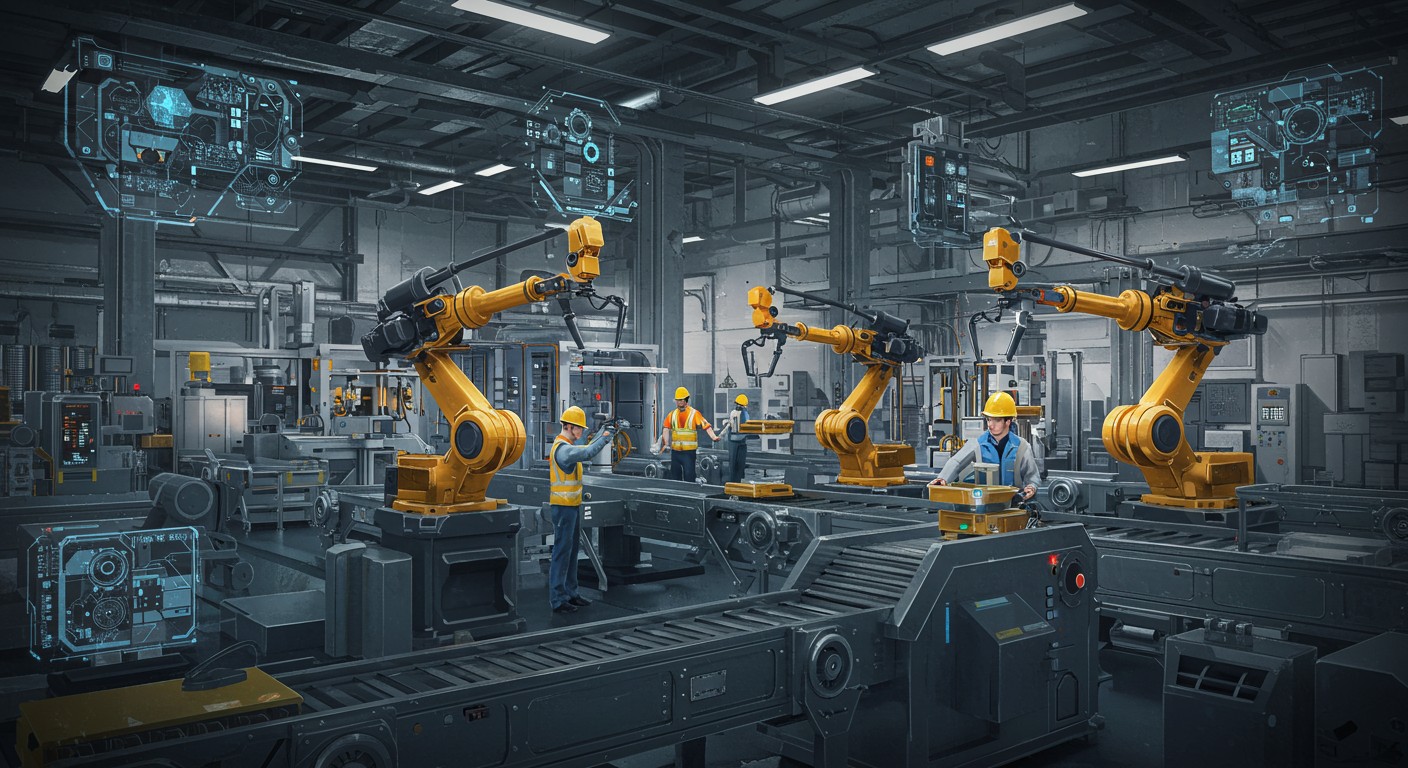

Mass production is all about creating large quantities of standardized goods using automated systems, assembly lines, and a clear division of labor. Think of it as a well-oiled machine: each part of the process is carefully designed to maximize output while keeping costs low. From cars to candy bars, this method has transformed how we produce and consume. But what exactly sets it apart?

The Core Elements of Mass Production

At its heart, mass production relies on a few key principles that make it both efficient and scalable. These aren’t just technical terms; they’re the building blocks of how industries operate today.

- Standardization: Products are designed to be identical, ensuring consistency and simplifying production.

- Automation: Machines and robots handle repetitive tasks, reducing human error and speeding things up.

- Division of Labor: Workers focus on specific tasks, becoming experts in their roles.

- Continuous Flow: Assembly lines keep production moving smoothly, like a river of goods.

These elements work together to create a system that’s fast, reliable, and cost-effective. But it wasn’t always this way. The story of mass production has deep roots, and it all started with a visionary who changed the game.

A Brief History: The Rise of the Assembly Line

Picture this: it’s the early 1900s, and cars are a luxury only the wealthy can afford. Then along comes Henry Ford, a man with a bold idea. In 1913, he introduced the moving assembly line at his Ford Motor Company factory. This wasn’t just a tweak to the production process—it was a revolution.

“The assembly line slashed the time it took to build a car from 12 hours to just 90 minutes.”

– Automotive historian

Ford’s innovation made the Model T affordable for the average person, turning cars into a household staple. By 1927, over 15 million Model Ts had rolled off the line. This breakthrough didn’t just transform the auto industry; it set the stage for mass production to dominate everything from electronics to food. I find it fascinating how one idea can ripple through history, don’t you?

Why Mass Production Wins: The Advantages

Mass production isn’t just a buzzword—it’s a powerhouse that drives economies. Its benefits are hard to ignore, and they’ve shaped the way businesses operate. Let’s break down why it’s such a big deal.

Unmatched Efficiency

Thanks to automation and streamlined processes, mass production churns out goods at a blistering pace. Machines don’t need coffee breaks, and assembly lines keep things moving 24/7. This speed translates to more products in less time, which is a win for both manufacturers and consumers.

Cost Savings That Add Up

One of the biggest perks of mass production is its ability to slash costs. By producing in bulk, companies benefit from economies of scale—the more you make, the cheaper each unit becomes. Fewer workers are needed, and automated systems reduce errors, saving money on fixes. These savings often trickle down to consumers, making products more affordable.

Consistency You Can Count On

Ever notice how every can of soda tastes the same? That’s mass production at work. Standardized processes ensure every product meets the same quality standards. This precision builds trust with customers and keeps brands reliable.

Fast Delivery to Market

In today’s fast-paced world, speed is everything. Mass production allows companies to stock shelves quickly, giving them a competitive edge. For example, fast-food chains rely on this efficiency to serve customers in minutes, not hours.

These advantages make mass production a cornerstone of modern industry. But as with anything, there’s a flip side. Let’s explore the challenges that come with this high-speed system.

The Downsides: Where Mass Production Falls Short

While mass production is a marvel of efficiency, it’s not perfect. There are real hurdles that manufacturers face, and some of these can have ripple effects on workers, consumers, and even the environment. Here’s a closer look at the drawbacks.

High Startup Costs

Setting up a mass production system isn’t cheap. Building factories, installing robotic arms, and designing assembly lines require a massive upfront investment. For smaller companies, this can be a dealbreaker. And if something goes wrong—like a design flaw—it’s not just a quick fix; it’s a costly overhaul.

Inflexibility in the Face of Change

Mass production thrives on repetition, but that can be a double-edged sword. If market trends shift or regulations change, retooling an assembly line can take months and millions. Imagine a company set up to produce one type of product, only to find demand has dried up. That’s a tough spot to be in.

The Human Cost

While automation reduces the need for workers, it can also lead to repetitive, mind-numbing tasks for those who remain. I’ve always thought there’s something tough about doing the same thing over and over. This monotony can sap morale, increase turnover, and even affect mental health. In some regions, low wages and poor working conditions add to the challenge.

Quality Risks

When you’re producing thousands of items a day, a single flaw can spiral into a massive problem. A defective part could mean recalling millions of products, damaging a brand’s reputation. It’s a high-stakes game where precision is non-negotiable.

| Aspect | Advantage | Disadvantage |

| Cost | Lower per-unit costs | High initial investment |

| Speed | Rapid production | Inflexible to changes |

| Quality | Consistent output | Risk of widespread defects |

| Labor | Fewer workers needed | Repetitive tasks, low morale |

These challenges remind us that mass production, while transformative, isn’t a one-size-fits-all solution. It’s a balancing act between efficiency and adaptability.

Real-World Examples of Mass Production

Mass production touches nearly every aspect of our lives. From the food we eat to the cars we drive, its influence is everywhere. Here are a few standout examples that show just how versatile this system is.

The Sweet Success of Candy

Ever heard of those iconic marshmallow treats shaped like chicks? Back in the 1950s, making one took 27 hours by hand. Today, thanks to mass production, it takes just six minutes. Over 5.5 million of these treats are churned out daily, proving how automation can turn a niche product into a global phenomenon.

Cars: From Luxury to Everyday

Ford’s assembly line didn’t just make cars—it made them accessible. By the 1960s, the company was using robots to handle heavy tasks like die-casting. Today, robotic arms are a staple in auto plants, ensuring precision and speed. It’s no wonder cars are now a part of everyday life.

Electronics for All

Smartphones, laptops, and TVs are mass-produced marvels. Companies use automated systems to assemble tiny components with pinpoint accuracy. This efficiency is why you can buy a high-quality device without breaking the bank. It’s mind-blowing when you think about the complexity involved.

These examples show how mass production has democratized access to goods. But what does the future hold for this industrial giant?

The Future of Mass Production

Mass production isn’t standing still. New technologies are pushing it into exciting territory, blending efficiency with flexibility. Here’s a peek at what’s on the horizon.

3D Printing: A Game Changer?

Some manufacturers are experimenting with 3D printing to create parts on demand. This could make production more customizable without sacrificing speed. Imagine a world where your sneakers are printed to fit your feet perfectly—pretty cool, right?

Smart Factories and AI

Artificial intelligence is making factories smarter. AI can predict equipment failures, optimize production schedules, and even catch defects before they spread. These “smart factories” are more efficient and adaptable, addressing some of mass production’s biggest pain points.

Sustainability in Focus

With growing environmental concerns, manufacturers are rethinking waste and energy use. Some are adopting eco-friendly materials or recycling systems to make mass production greener. It’s a step toward balancing profit with planet, and I’m all for it.

“The future of manufacturing lies in blending automation with sustainability.”

– Industry analyst

These innovations suggest mass production is evolving to meet modern challenges. It’s not just about making more—it’s about making better.

The Bottom Line

Mass production has reshaped the world, making goods affordable and accessible while driving industrial progress. Its strengths—efficiency, cost savings, and consistency—have fueled economic growth and innovation. Yet, challenges like high costs, inflexibility, and worker morale remind us it’s not flawless. As technology advances, from AI to 3D printing, mass production is poised to become smarter and more sustainable.

Perhaps the most interesting aspect is its duality: it’s both a triumph of human ingenuity and a puzzle that keeps evolving. Whether you’re marveling at a perfectly made smartphone or grabbing a quick burger, mass production is behind it all. So, next time you pick up a mass-produced item, take a moment to appreciate the complex system that brought it to you—and the future it’s still shaping.