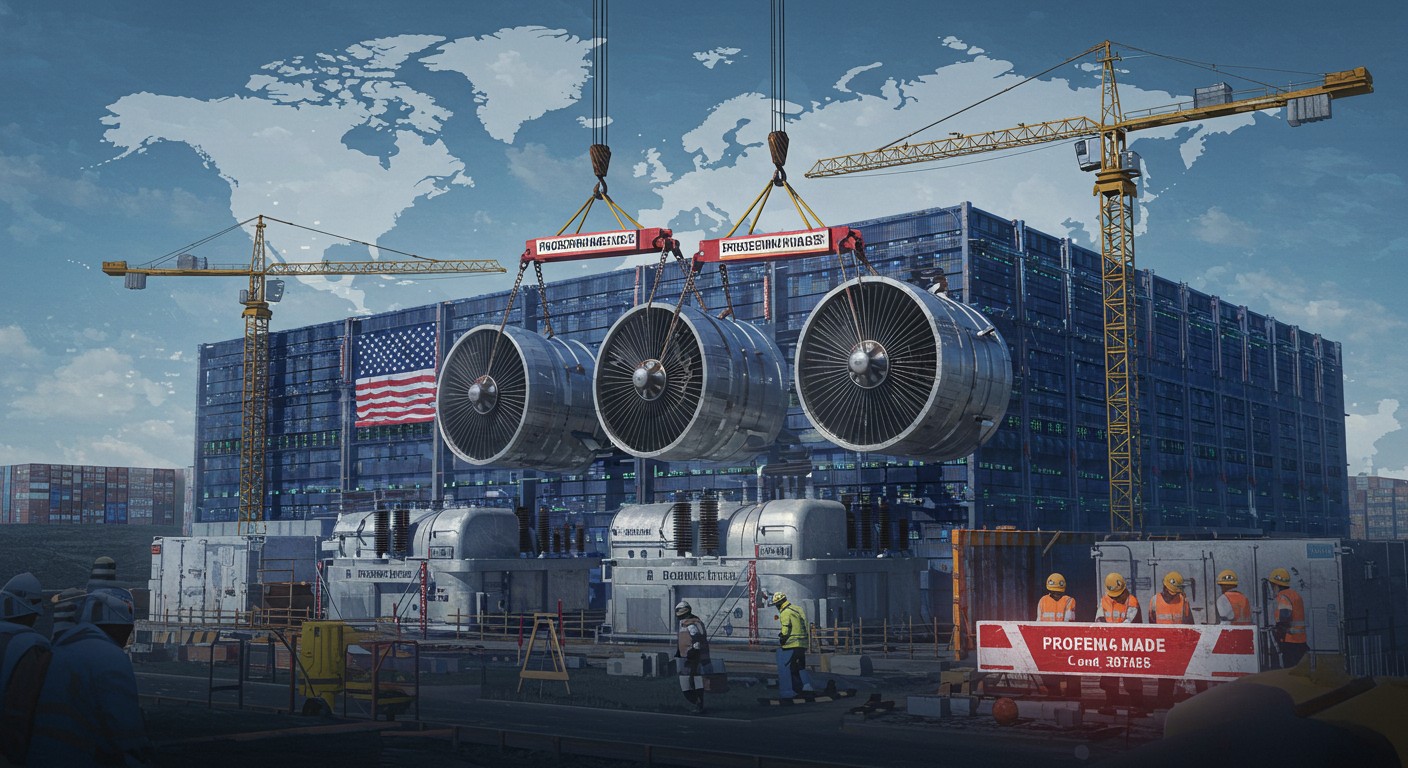

Have you ever wondered what it takes to power the tech revolution sweeping the globe? The recent buzz around massive investments in artificial intelligence infrastructure—think billion-dollar data centers and power plants—has thrust the U.S. supply chain into the spotlight. It’s a fascinating, if sobering, reality check: building the future of AI isn’t just about coding and innovation; it’s about nuts, bolts, and a whole lot of global cooperation.

The Hidden Hurdles of America’s AI Ambitions

The U.S. is racing to lead the AI revolution, but the supply chain underpinning these ambitious projects tells a different story. From gas turbines to steel, the components needed to construct cutting-edge data centers and power plants often come from far beyond American borders. This reliance on foreign suppliers, coupled with labor shortages and tariff pressures, is creating a perfect storm that could slow progress. Let’s dive into the challenges and what they mean for the future.

Foreign Dependency in Critical Components

Building a data center or power plant isn’t like assembling a DIY bookshelf. These projects require specialized equipment—massive, precision-engineered parts that are both costly and complex. According to industry experts, the U.S. doesn’t produce many of these components domestically, leaving companies to rely heavily on international manufacturers. This dependency isn’t just a logistical hiccup; it’s a strategic vulnerability.

“The U.S. is grappling with a supply chain that’s heavily reliant on foreign expertise for critical infrastructure.”

– Supply chain analyst

Take gas turbines, for example. These behemoths are essential for powering large-scale AI facilities. The global market for heavy-duty turbines is dominated by a handful of players, including companies based in Germany and Japan. Data suggests nearly 50% of new turbine supply comes from foreign sources, meaning U.S. projects are at the mercy of global production schedules and shipping logistics.

Nuclear Components: A Domestic Drought

Then there’s the nuclear sector. If you thought gas turbines were niche, consider the ultra-large forgings needed for nuclear reactors. These massive components, like reactor pressure vessels, are no longer made in the U.S. at scale. For instance, the reactors at a recently built nuclear plant in Georgia relied on parts fabricated in South Korea. This isn’t just a one-off; it’s a sign of a broader trend where domestic manufacturing has lagged behind global competitors.

Why does this matter? Because every shipment from overseas introduces delays, costs, and risks. A single missing component can halt a multi-billion-dollar project. In my view, it’s a bit like trying to bake a cake without flour—you can have all the other ingredients, but you’re stuck until that key piece arrives.

Transformers and Steel: The Global Backbone

Power distribution is another weak link. High-voltage transformers, which connect power plants to the electrical grid, are critical for AI infrastructure. Yet, over 80% of these transformers are manufactured abroad, in countries like South Korea, Germany, and Canada. This heavy reliance on foreign suppliers means U.S. projects face not just supply chain bottlenecks but also the whims of international trade policies.

Steel, too, poses a challenge. While the U.S. produces significant amounts of steel, project developers often turn to imports to meet cost and capacity needs. Tariffs on foreign steel can jack up prices, adding millions to project budgets. It’s a classic case of being caught between a rock and a hard place: pay more for domestic materials or deal with the complexities of importing.

The Tariff Trap: Costly Complications

Tariffs are like that unexpected bill you get right before payday—they hit hard and mess up your plans. For AI infrastructure projects, tariffs on imported components like steel, aluminum, and specialized equipment can increase costs by 3% to 6%. On a multi-billion-dollar project, that’s hundreds of millions of dollars in added expenses. And that’s just for raw materials; factor in turbines and transformers, and the numbers climb even higher.

Some allied countries, like the U.K., are exempt from certain tariffs, which helps a bit. But the sheer scale of these projects means even small price hikes add up fast. Experts warn that tariffs, combined with already strained supply chains, could turn these ambitious AI plans into logistical nightmares.

“Tariffs and sourcing realities make this AI build-out a significant trade policy challenge.”

– Industry expert

Labor Shortages: The Human Element

If components are the backbone of AI infrastructure, skilled labor is the muscle. And right now, the U.S. is facing a serious labor shortage. Building these facilities requires welders, machinists, electricians, and other specialized workers—many of whom are in short supply. Industry analysts describe the need for a “wartime-like” expansion of the workforce to meet demand. That’s a tall order when skilled trades are already in decline.

I find this part particularly striking. We’re talking about cutting-edge technology, yet the bottleneck might come down to something as fundamental as not having enough trained hands on deck. It’s a reminder that even the most futuristic projects rely on human expertise.

What’s at Stake for AI’s Future?

The challenges don’t end with logistics and labor. The broader implications of this supply chain crunch could ripple across the AI industry. Delays in building data centers and power plants could slow the rollout of new AI technologies, giving other countries a chance to catch up in the global tech race. Plus, the added costs from tariffs and foreign sourcing could make these projects less financially viable.

Here’s a quick breakdown of the key issues:

- Foreign-sourced components: Nearly half of turbines and most transformers come from abroad.

- Tariff costs: A 3%–6% price hike can add hundreds of millions to project budgets.

- Labor shortages: A lack of skilled workers could delay construction timelines.

- Strategic risks: Over-reliance on foreign suppliers exposes projects to global disruptions.

Can the U.S. Rise to the Challenge?

So, what’s the path forward? Some experts suggest investing in domestic manufacturing to reduce reliance on foreign suppliers. Others argue for streamlining trade policies to minimize tariff impacts. Then there’s the labor issue—training programs and incentives could help rebuild the skilled workforce needed for these projects.

Personally, I think the solution lies in a mix of all three. Boosting domestic production sounds great, but it’s a long-term fix for a short-term problem. In the meantime, smarter trade policies and a serious push to train workers could keep these projects on track. It’s not going to be easy, but when has building the future ever been?

A Global Effort for a Local Goal

At its core, the AI boom is a global endeavor. The U.S. may lead in innovation, but it leans on the world for the raw materials and expertise to make it happen. This interconnectedness is both a strength and a vulnerability. As projects like these move forward, the ability to navigate supply chain complexities will determine whether the U.S. can maintain its edge in AI.

What fascinates me most is how this situation mirrors broader trends. Whether it’s tech, energy, or even consumer goods, global supply chains are the backbone of modern progress. Yet, they’re also the Achilles’ heel when things go wrong. Perhaps the real lesson here is that no country, no matter how powerful, can go it alone.

“The future of AI depends on global cooperation as much as it does on local innovation.”

– Tech industry analyst

As the U.S. pushes to build the infrastructure for the next generation of AI, it’s clear that the road ahead is fraught with challenges. From foreign-sourced components to labor shortages, the supply chain is a puzzle that needs solving. But with the right mix of policy, investment, and grit, America just might pull it off.

What do you think—can the U.S. overcome these hurdles and lead the AI revolution? The answer might depend on how well we play the global game.