Have you ever wondered what it’ll take for electric vehicles to become as common as gas-powered cars? I’ve been fascinated by the shift toward sustainable transport, and the latest news from Tennessee has me buzzing with excitement. A major collaboration between two industry giants is poised to make electric vehicle (EV) batteries more affordable than ever, potentially changing the game for drivers and the planet alike. This isn’t just another factory upgrade—it’s a bold step toward a future where EVs aren’t a luxury but a practical choice for everyone.

A New Era for EV Battery Production

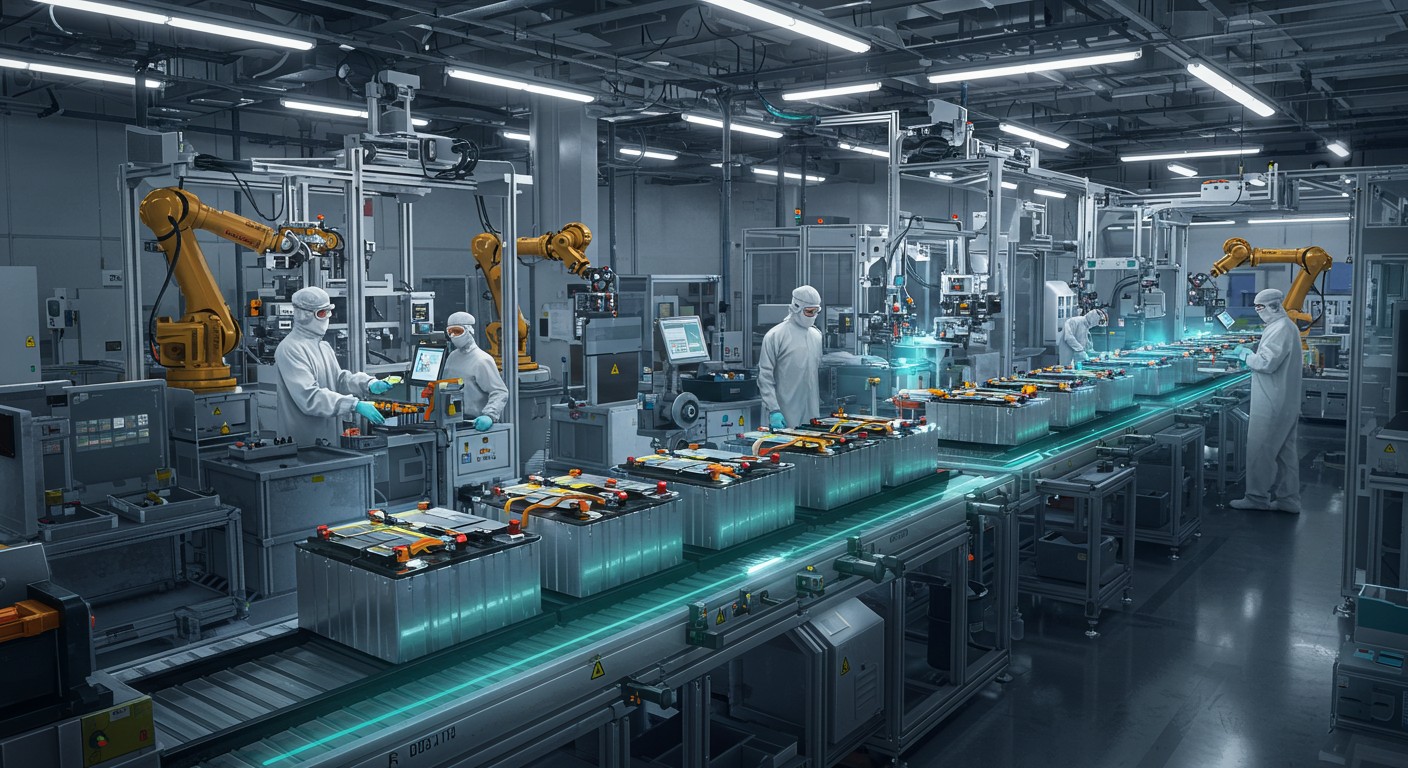

The push for greener transportation has been gaining momentum, but one hurdle has always loomed large: the cost of EV batteries. That’s where a groundbreaking development in Spring Hill, Tennessee, comes into play. A joint venture between two leading automotive and energy companies is upgrading a state-of-the-art facility to produce lithium iron phosphate (LFP) battery cells. These batteries promise to be a game-changer, offering a cheaper, more sustainable alternative to traditional lithium-ion batteries. I can’t help but think this could be the spark that accelerates EV adoption across the board.

Why LFP Batteries Matter

So, what’s the big deal about LFP batteries? Unlike standard lithium-ion batteries, which rely on pricey minerals like cobalt and nickel, LFP batteries use more abundant and less expensive materials. This makes them significantly cheaper to produce, which could translate to lower prices for EVs. But it’s not just about cost—LFP batteries are also known for their durability and safety, making them a win-win for manufacturers and consumers alike.

LFP batteries could redefine the economics of electric vehicles, making them accessible to a wider audience.

– Industry expert on battery technology

The implications are huge. Imagine a world where EVs aren’t just for the environmentally conscious elite but for everyday folks looking to save money at the pump. By cutting out costly minerals, this Tennessee facility is paving the way for EVs that are both eco-friendly and wallet-friendly. In my opinion, this kind of innovation is exactly what the industry needs to bridge the gap between aspiration and reality.

The Tennessee Upgrade: What’s Happening?

The Spring Hill facility, a hub of cutting-edge battery production, is getting a major overhaul to focus on LFP technology. This upgrade isn’t just a minor tweak—it’s a strategic move to scale up production of these cost-effective cells. The joint venture behind the plant has already invested billions to make it a cornerstone of EV battery manufacturing in the U.S., and this latest announcement builds on that foundation.

- Cost savings: LFP batteries eliminate the need for expensive cobalt and nickel.

- Scalability: The upgraded facility will produce batteries at a volume that could meet growing demand.

- Sustainability: Using abundant materials reduces environmental impact.

Production of these LFP cells is expected to kick off by late 2027, which feels like a lifetime away but is a blink in the world of industrial timelines. What excites me most is how this move diversifies the types of batteries available for EVs, giving manufacturers more flexibility to cater to different markets and price points.

How This Fits into the Bigger EV Picture

The EV market is at a crossroads. While enthusiasm for electric cars is high, adoption has been slower than some predicted, largely due to high upfront costs. Batteries account for a significant chunk of an EV’s price tag, so innovations like LFP could be the key to unlocking broader market appeal. I’ve always believed that affordability is the secret sauce for mainstream EV adoption, and this Tennessee project seems to agree.

| Battery Type | Key Materials | Cost Impact |

| Lithium-Ion | Cobalt, Nickel | High |

| LFP | Iron, Phosphate | Low-Medium |

| Future Innovations | Varies | Potentially Low |

The table above highlights why LFP is such a big deal. By swapping out costly materials, manufacturers can pass savings on to consumers, making EVs more competitive with traditional gas-powered cars. Plus, with a major automaker already offering a dozen EV models ranging from budget-friendly to luxury, the addition of LFP batteries could further broaden their appeal.

The Ripple Effects of Cheaper Batteries

Lower-cost batteries don’t just mean cheaper EVs—they could reshape the entire automotive landscape. For starters, they could make electric SUVs and trucks more affordable, addressing a segment where range and power are critical. I can’t help but imagine families opting for an electric pickup for their weekend adventures, knowing it’s both practical and budget-conscious.

- Market expansion: Affordable EVs could attract new buyers, from young professionals to retirees.

- Environmental impact: More EVs on the road means fewer emissions, a win for the planet.

- Industry competition: Lower costs could spark a race among automakers to innovate further.

Perhaps the most exciting part is how this could accelerate the shift away from fossil fuels. Every EV sold is a step toward cleaner air, and if LFP batteries make that transition more affordable, we might see gas stations become a thing of the past sooner than expected. It’s a bold vision, but one that feels increasingly within reach.

Challenges and Opportunities Ahead

Of course, no innovation comes without hurdles. Scaling up LFP production will require precision and investment, and the timeline of late 2027 means we’ll need to be patient. There’s also the question of how LFP batteries will stack up in terms of range and performance compared to their high-nickel counterparts. In my experience, though, the trade-offs are often worth it when the end result is a more accessible product.

The future of EVs depends on balancing cost, performance, and sustainability.

– Automotive industry analyst

Another challenge is consumer perception. Some buyers might worry that “cheaper” batteries mean lower quality, but LFP’s track record in safety and longevity should put those fears to rest. The opportunity here is clear: if manufacturers can communicate the value of LFP technology, they could win over a whole new wave of EV enthusiasts.

What This Means for Investors

For those with a keen eye on the market, this Tennessee upgrade is worth watching. The shift to LFP batteries could signal a broader trend in the automotive and energy sectors, creating opportunities for investors in battery technology, EVs, and related supply chains. I’ve always found that innovations like this tend to ripple through the market, boosting companies that are quick to adapt.

Investment Potential in EV Battery Tech: 50% Battery Manufacturers 30% EV Automakers 20% Raw Material Suppliers

While I’m no financial advisor, it’s hard to ignore the potential here. Companies involved in LFP production or EV manufacturing could see a surge in interest as this technology gains traction. It’s a reminder that staying ahead of the curve in sustainable tech can pay off in more ways than one.

Looking to the Future

As I reflect on this development, I can’t help but feel optimistic about where the EV industry is headed. The Tennessee plant upgrade is more than just a factory tweak—it’s a symbol of progress in the quest for sustainable, affordable transportation. By making EVs more accessible, this initiative could redefine how we think about mobility, from city commutes to cross-country road trips.

What’s next? Only time will tell, but one thing’s for sure: the road to a greener future is looking brighter. Whether you’re an EV enthusiast, an investor, or just someone curious about the future of transportation, this is a story worth following. Who knows—maybe your next car will be powered by one of these innovative batteries.