Ever wondered what happens to that old smartphone gathering dust in your drawer? Or the laptop you replaced because it couldn’t keep up with your latest software? Most of us don’t give these devices a second thought once they’re out of sight, but they’re more than just forgotten gadgets—they’re potential goldmines. Not literally, of course, but in a world scrambling for rare earth metals and critical minerals, these discarded electronics are sparking a revolution in how we source materials for everything from electric vehicles to fighter jets.

The Growing Importance of E-Waste Recycling

The global race for technological dominance has put a spotlight on rare earth elements—materials like neodymium, dysprosium, and praseodymium that power modern devices. These elements are vital for manufacturing everything from wind turbines to smartphones, but here’s the kicker: the supply chain is shaky. With one country dominating the market and geopolitical tensions throwing wrenches into trade, industries are desperate for alternatives. That’s where e-waste recycling comes in, turning old tech into a treasure trove of resources.

Recycling e-waste is no longer just about reducing landfill—it’s about securing the materials that drive our future.

– Industry recycling expert

I’ve always been fascinated by how something as simple as an old phone can hold the key to solving complex global problems. The idea that my outdated device could help fuel the next generation of green tech? That’s the kind of innovation that gets me excited. But let’s break down why this matters and how it’s reshaping industries.

Why Rare Earths Are the New Gold

Rare earth elements are the unsung heroes of modern technology. They’re used in magnets for electric vehicle motors, wind turbines, and even military equipment. The problem? Over 90% of the global supply is controlled by a single nation, making the market vulnerable to trade disputes and export restrictions. When tariffs or bans disrupt the flow, industries grind to a halt. I remember reading about a major automaker pausing production because of a magnet shortage—crazy, right?

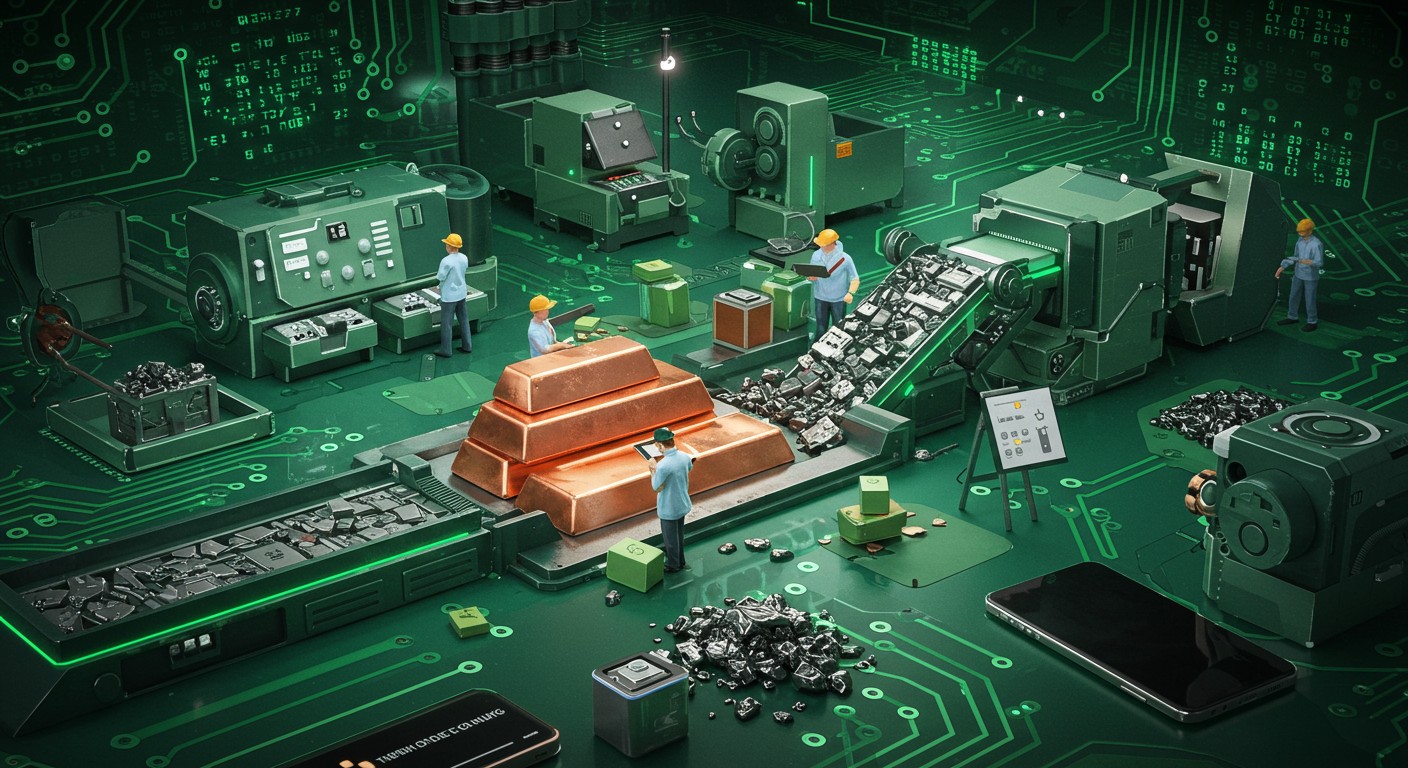

Here’s where e-waste steps in. Old electronics are packed with these valuable materials. A single hard drive might contain neodymium, while a smartphone could yield gold, copper, or even lithium. By recycling these devices, we’re not just reducing waste—we’re tapping into a domestic supply of critical resources.

- Neodymium and Praseodymium: Found in hard drives and EV motors, critical for magnets.

- Gold and Silver: Hidden in circuit boards, used in countless electronics.

- Lithium and Cobalt: Key components in batteries for EVs and renewable energy storage.

The beauty of this approach is its dual benefit: it reduces reliance on foreign suppliers and keeps valuable materials out of landfills. But it’s not just about rare earths—common metals like copper and aluminum are in high demand too, and recycling them is often faster and cheaper than mining.

The E-Waste Boom: A Growing Opportunity

Let’s talk numbers for a second. In 2022, the world generated a staggering 62 million metric tons of e-waste, and that figure is expected to hit 82 million by 2030. The U.S. alone produced nearly 8 million tons, but here’s the shocker: only about 15-20% of it is properly recycled. That’s a massive untapped resource sitting in warehouses, landfills, or your junk drawer.

E-waste is a sleeping giant. It’s not just waste—it’s a resource we’ve barely begun to tap.

– Global recycling industry leader

The recycling industry is catching on. Companies are investing heavily in facilities to process everything from old TVs to spent EV batteries. In my view, this is a game-changer. Instead of shipping our e-waste overseas or letting it pile up, we’re starting to see it as a strategic asset. New plants in places like Kentucky and Georgia are popping up to handle copper, aluminum, and rare earths, creating jobs and boosting local economies.

| Material | Source | Application |

| Copper | Circuit boards, wires | Electronics, EV batteries |

| Rare Earths | Hard drives, motors | Magnets, renewable energy |

| Lithium | Batteries | EV and energy storage |

These facilities aren’t just about crunching old gadgets—they’re about precision. Advanced sorting and smelting processes ensure that even tiny amounts of rare earths are recovered efficiently. It’s like panning for gold, but with circuit boards instead of riverbeds.

Geopolitics and the Push for Domestic Supply

The global supply chain for critical minerals has been rocked by trade wars and tariffs. When one country can choke off 90% of the world’s rare earth supply, it’s a wake-up call. Recent moves, like export restrictions on key materials, have left manufacturers scrambling. I can’t help but think we’ve been too complacent, relying on foreign sources while our own resources sit in landfills.

The U.S. government is stepping up. Investments in domestic mining, like the recent equity stake in a California rare earths mine, are a start. But mining takes decades to scale up—recycling doesn’t. By processing e-waste locally, we can reduce dependence on unpredictable imports and build a more resilient supply chain.

- Reduce Foreign Dependence: Recycling e-waste provides a local source of critical materials.

- Faster Turnaround: Unlike mining, recycling can scale up quickly to meet demand.

- Environmental Win: Keeps hazardous materials out of landfills and reduces mining’s ecological footprint.

Perhaps the most exciting part is how this shift is spurring innovation. Startups are developing cutting-edge technologies to extract rare earths from hard drives and batteries, while established companies are expanding their recycling operations. It’s a win-win for the economy and the environment.

The Role of Startups in the Recycling Revolution

While big players have long dominated recycling, startups are stealing the show with bold ideas. Some focus on specific niches, like recovering rare earths from hard drives or lithium from EV batteries. Others are building entire ecosystems to process e-waste from start to finish. I find it inspiring to see entrepreneurs tackle such a complex problem with creativity and grit.

Take battery recycling, for instance. With electric vehicles booming, the demand for lithium, cobalt, and nickel is skyrocketing. Startups are stepping in with processes that recover these materials at a fraction of the cost of mining. One company I came across even uses old EV motors to extract rare earths for new magnets. It’s like closing the loop on the tech lifecycle.

Startups are proving that innovation can turn waste into wealth.

– Technology entrepreneur

But it’s not all smooth sailing. Some startups rely heavily on government incentives, which can be a risky bet if policies change. My advice? Focus on solid business fundamentals, not just flashy tech. A great idea won’t survive without a sustainable model.

Challenges and Risks in E-Waste Recycling

Recycling e-waste isn’t as simple as tossing old phones into a bin. For one, data security is a massive concern. Devices like smartphones and servers often contain sensitive information, so proper IT asset disposition (ITAD) is critical to comply with cybersecurity regulations. Companies specializing in this ensure data is wiped before recycling begins.

Then there’s the issue of scale. While the industry is growing—generating $28.1 billion in 2024, with an 8% annual growth rate—it’s still a drop in the bucket compared to global demand. Recycling facilities need to process massive volumes to make a dent, and that requires investment, infrastructure, and expertise.

- Data Security: Ensuring sensitive information is destroyed before recycling.

- Scalability: Building facilities to handle growing e-waste volumes.

- Cost Efficiency: Making recycling competitive with mining.

Investing in recycling startups can also be a gamble. Some have burned through cash on unproven technologies or relied too heavily on subsidies. I’ve seen promising companies stumble because they didn’t plan for long-term viability. Still, the potential is huge, and the right players could reshape the industry.

What’s Next for E-Waste and Rare Earths?

Looking ahead, the e-waste recycling industry is poised for explosive growth. As demand for critical minerals surges, recycling will play a bigger role in securing supply chains. Governments, corporations, and consumers are all starting to see the value in turning old tech into new resources. But can we scale up fast enough to meet the needs of a tech-hungry world?

I believe we’re at a tipping point. The combination of geopolitical pressures, environmental concerns, and technological innovation is creating a perfect storm for e-waste recycling. Companies that can crack the code—balancing efficiency, scalability, and sustainability—will lead the charge.

E-Waste Recycling Impact Model: 50% Supply Chain Resilience 30% Environmental Benefits 20% Economic Growth

So, next time you’re about to toss out an old device, think twice. That outdated phone or laptop might just be the key to powering the future. And in a world where resources are increasingly scarce, that’s a pretty exciting thought.